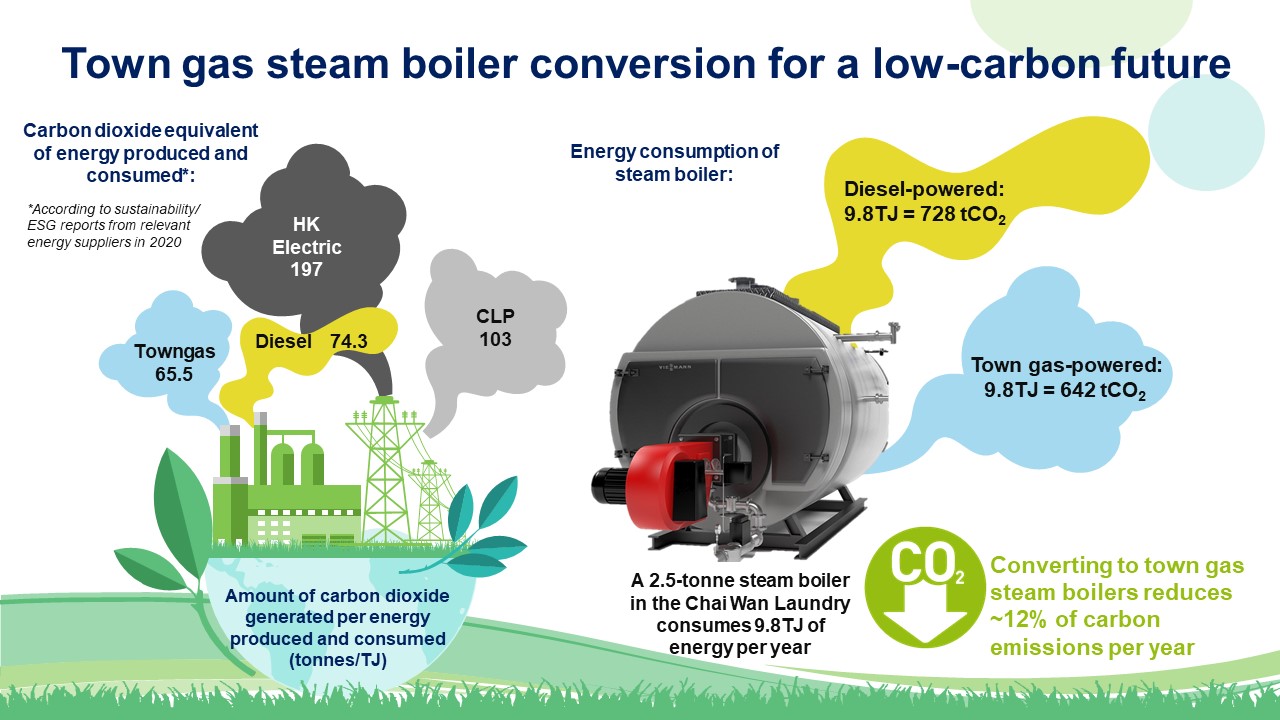

As a responsible energy supplier, Towngas strives to create a sustainable future. As far back as 1970s, the Company switched the production feedstock from coal and heavy oil to naphtha, and successively introduced natural gas and landfill gas in recent years in order to significantly reduce greenhouse gas emissions during energy production. As a result, the production of town gas emits less carbon dioxide than electricity and even diesel, making it a relatively clean and highly efficient energy.

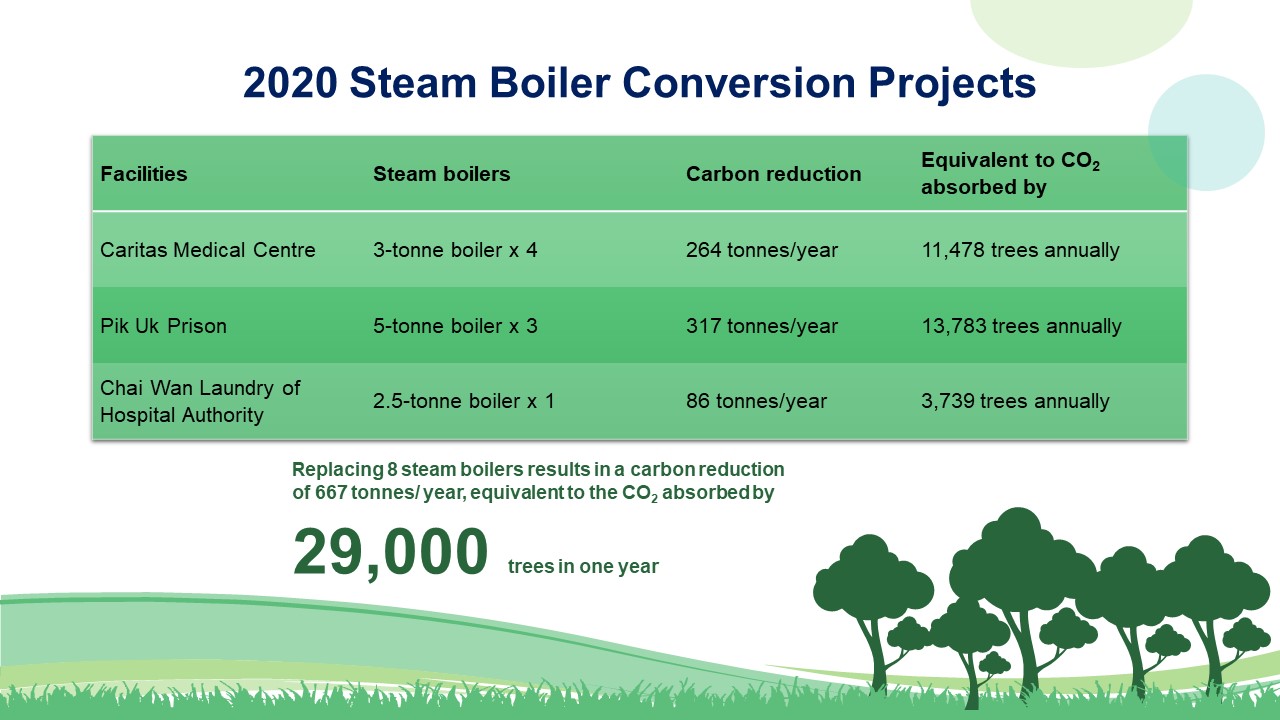

Aside from raw materials, Towngas also places an emphasis on the formulation of emission reduction strategies for its commercial and industrial clients. The town gas steam boiler produces stable and high-quality steam has seen wide applications in a vast range of sectors, including food manufacturing, shower, disinfection, space heating, laundry and more, with users spanning the manufacturing, hospitals, hotels and recreational and public facilities. As the town gas steam boiler emits about 12 per cent less carbon than its traditional diesel-powered counterpart, Towngas’ Commercial & Industrial Marketing & Sales Department has strongly promoted the relevant replacement, proactively encouraging steam boiler users to switch to green town gas alternatives. In 2020, Towngas established gas connections for Caritas Medical Centre, the Chai Wan Laundry of the Hospital Authority and Pik Uk Prison to offer stable gas supply for their steam boilers, expanding the commercial and industrial applications of town gas while reducing its clients’ carbon emissions.

Caritas Medical Centre decommissioned its diesel boilers in stages and replaced them with four three-tonne dual fuel steam boilers, using town gas as the main fuel to produce steam for patient bathing, medical equipment disinfection and laundry.

Pik Uk Prison decommissioned its diesel boilers in stages and replaceed them with three five-tonne boilers to produce steam for the washing and drying facilities in its laundry workshop. The continuous gas supply from the pipelines effectively eliminates the past security risks posed by the heavy trucks accessing the institution for regular diesel refilling.

The Hospital Authority’s Chai Wan Laundry has converted to a 2.5-tonne boiler to produce steam from town gas to supply the washing, drying, folding and ironing facilities in its workshop.

Adopting the clean energy of town gas effectively reduces the negative impact presented by diesel use, with the following benefits:

1) Significantly reduces the soot produced in the boiler

2) Eliminates unpleasant smells resulting from diesel refilling

3) Great savings on maintenance cost due to smooth operation ensured by regular maintenance

Using town gas as its main fuel helps reduce greenhouse gases such as carbon dioxide, sulphur dioxide and nitrous oxide. For instance, the replacement of the eight boilers in the three aforementioned facilities results in an annual reduction of 667 tonnes of carbon emissions, equivalent to the annual carbon consumption of 29,000 trees. As a green enterprise, Towngas will continue to seek ways to help its clients reduce greenhouse gas emissions in order to attain a low carbon future together.